EPAC Kletterfilmverdampfer, computergesteuert.

INNOVATIVE SYSTEME

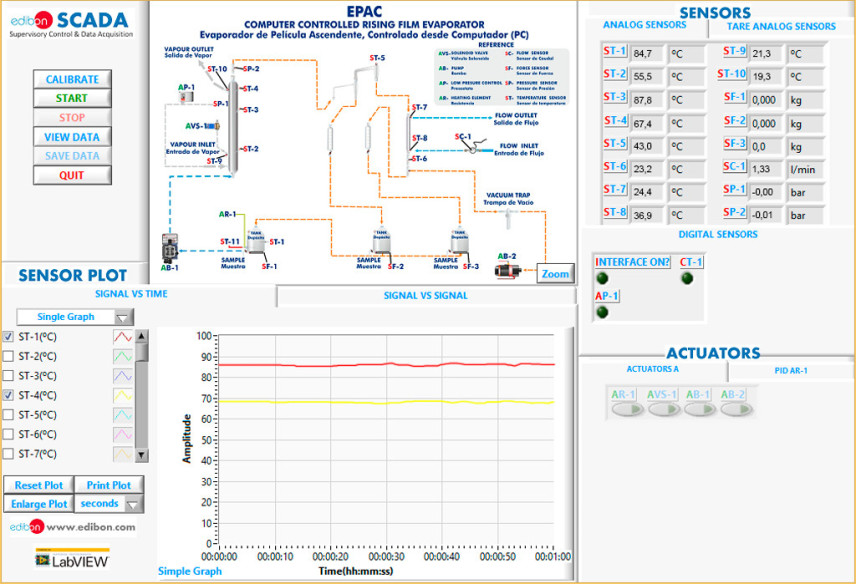

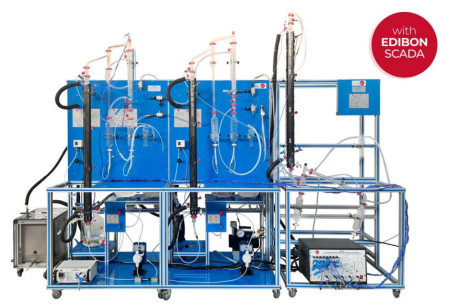

The Computer Controlled Rising Film Evaporator, "EPAC", has been designed by EDIBON to study the operating processes of a rising film evaporator. It allows the follow-up and monitoring from the computer of all the variables for a complete study of the process according to the working conditions and to investigate the effects of the variation of parameters of the process such as: vacuum, temperature, flow, etc in the ascending film evaporation.

Erweiterungen

Laboratorien

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

The objective of evaporation is to concentrate a non-volatile solute, carrying out the elimination of a volatile compound. Water is the volatile compound used in most evaporations.

The rising or falling film evaporators are very useful if high temperatures can degrade the product that we want to concentrate, so these evaporators work at less temperature. They can be used, for example, for concentration of fruit juices, milk and milk products, effluents, etc.

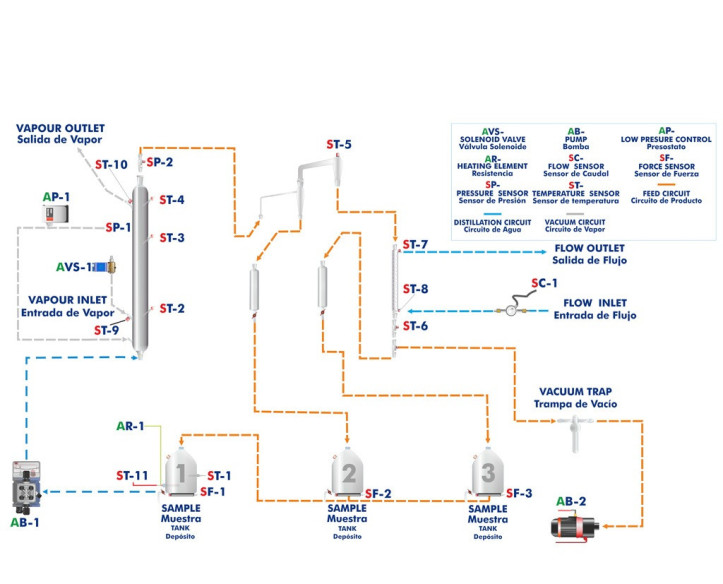

Basically, the unit consists of the following circuits:

- The feed circuit that consists on a feed pump that introduces the product in a double jacket column, which has temperature sensors. The product leaves the tank through a cyclone placed at the output of the column and it is collected in a 500 ml graduated vessel. The vessel is also connected to a 10 l. tank for the storage of the concentrated product. This last tank is connected to the feed tank for its recirculation.

- The distillation circuit starts at the top of the column, where a joint with a pressure sensor has been assembled. It is also connected to the cyclone to separate the concentrated product and the distilled one that goes through a spiral condenser. The distilled product is stored in a graduated vessel that is connected to a 10 l. collection tank. This last one is connected to the feed tank for its recirculation in a continuous process.

- The steam circuit, introduced in the external jacket of the column, contains a pressure sensor for the control of the temperature of steam. This sensor is connected to a high-pressure cutout control that opens or closes a control electrovalve for the steam supply.

- The vacuum circuit consists on a vacuum pump, one trap placed at the output of the condenser and other trap placed at the output of the cyclone.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit self + a Control Interface Box + a Data Acquisition Board + Computer Control and Data Acquisition Software Packages, for controlling the process and all parameters involved in the process.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Determination of the capacity of the evaporator.

- Study of the capacity of the evaporator in function of the work conditions.

- Study of the relation between condensed product and evaporated product.

- Verification of the mass balance over all system.

- Study of the mass balance of the solute.

- Verification of the mass balance of the water.

- Determination of the concentration of a sugared solution.

- Calculate the enthalpy of the volatile vapours.

- Calculate the mass of steam is used by means of an energy balance calculation.

- Determination the economy of evaporator.

- Energy balance of the tubular condenser.

- Determination of the heat transfer global coefficient.

- Determination of the C coefficient for a tubular condenser.

- Investigation of effect of varying process parameters such as:vacuum, flow rate, temperature, recycle rate.

- Fruit juices and vegetable extracts concentration.

- Concentrated milk obtaining .

- Determination of the efficiency of the steam generator.

- Sensors calibration.

MEHR PRAKTISCHE ÜBUNGEN FÜR DAS GERÄT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the EPAC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the EPAC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

ÄHNLICHE VERFÜGBARE GERÄTE

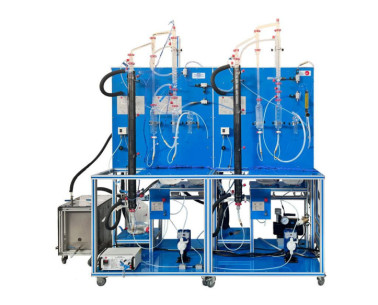

Kletterfilmverdampfer.

Doppel-Effekt- Kletterfilmverdampfer.

Fallfilmverdampfer, computergesteuert.

ERGÄNZENDE AUSRÜSTUNG

Computer Controlled and Touch Screen 0.4 l/h Carver-Greenfield Evaporator

Kletterfilmverdampfer.

Fallfilmverdampfer, computergesteuert.

Doppel-Effekt- Kletterfilmverdampfer, computergesteuert.

Doppel-Effekt- Kletterfilmverdampfer.

Computer Controlled Thin Film Evaporator

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen