Mechatronic Engineering represents the perfect synergy between mechanics and electronics. It's a holistic approach that integrates mechanical engineering, electronics, and automatic control to create intelligent systems and products. From industrial robots to production control systems,...

On December 1st, the Repair Course for Small Laboratory Equipment, taught by our engineers at the EDIBON facilities, was completed, lasting 4 days.

The attendees, (Laboratory technicians and maintenance of the Rey Juan Carlos University of Madrid) had the opportunity to perform multiple...

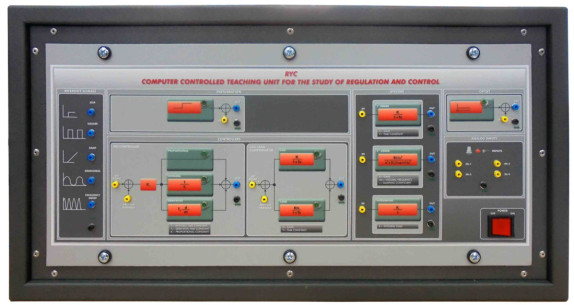

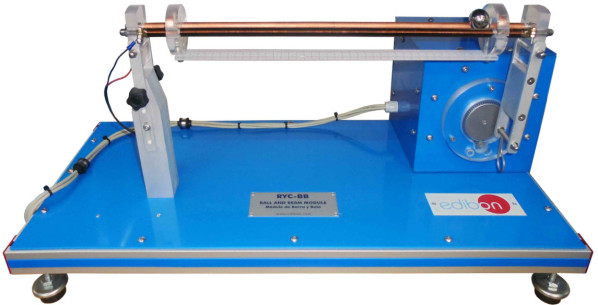

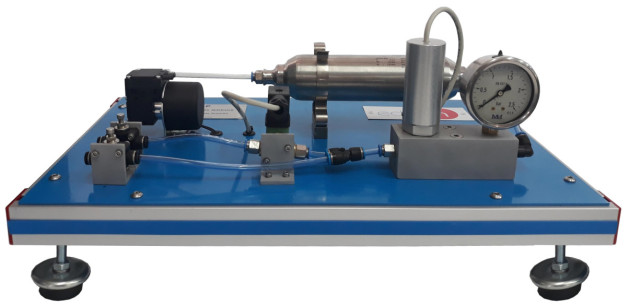

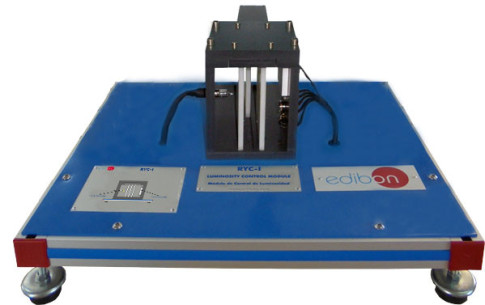

On October 19th, the Course on Instrumentation, Regulation and Control in Laboratories, taught by our engineers in these facilities, using EDIBON units, was completed and aimed at learning the control of the conditions of a laboratory process.

The attendants, (12 laboratory technicians and...

Cookie-Präferenzen

Cookie-Präferenzen