Computer Controlled Modular Hydraulic Turbine Unit,"HTMC", has been designed by EDIBON for the study and comparison of different types of small scale hydraulic turbines, allowing the determine the operation characteristics of this type of turbine, the hydraulic and mechanical efficiency curves, to obtain the hydraulic and mechanical power, etc.

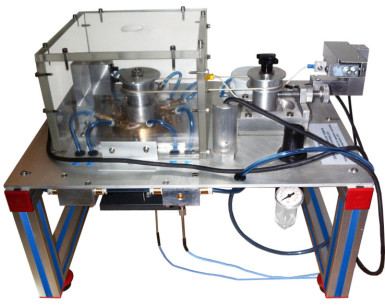

The minimum supply consists of two main elements: the Hydraulic Turbines Base Unit, "HT-UB", and at least one of the required elements described below.

The Hydraulic Turbines Base Unit, "HT-UB", fulfills the following functions:

- In order to raise the fluid, it has a computer controlled pump that enables the impelled flow to pass through the turbine, in which part of its energy is left, causing the turbine to turn, overcoming the external resistance caused by an electromagnetic brake. This computer controlled brake makes it possible to vary the braking load on the turbine.

- Measurement of the pressure at the pump inlet and outlet, in order to obtain its characteristic curve.

- Measurement of the water flow, the pressure at the water inlet to the turbine and the speed of the turbine shaft by means of different instrumentation.

- The pump-turbine group has a tank and a pipes system which allow to work constantly with recirculated fluid to avoid the indiscriminate water consumption.

Required elements (at least one) (Not included):

- HT-F: The Francis Turbine Model, "HT-F", consists of a small-scale Francis Turbine, with a valve that allows flow regulation and has a ring with adjustable guide vanes that allows control of the angle of incidence of the water in the turbine.

- HT-FA: The Axial Flow Turbine Model, "HT-FA", consists of a small-scale turbine with single-stage axial flow input. It has eight nozzles that act as water rings the rotor, four of which have an incidence angle of 20° and the other four of 30°. In this way, it is possible to study the differences in the working regime by varying the entry angles into the turbine through eight valves that allow the water to pass to the different nozzles.

- HT-FR: The Radial Flow Turbine Model, "HT-FR", consists of a small-scale radial flow turbine with two nozzles at 90° to the perpendicular direction of the axis of rotation.

- HT-P: The Pelton Turbine Model, "HT-P", consists of a small-scale Pelton turbine, with a valve that allows the flow to be regulated. The turbine includes a PELTON runner with 16 buckets, which can be clearly seen through the turbine’s transparent casing.

- HT-K: The Kaplan Turbine Model, "HT-K", consists of a small-scale Kaplan turbine that has a ring with adjustable guide vanes, which allow the control of water flow in the turbine.

Cookie-Präferenzen

Cookie-Präferenzen