IYDC Computer Controlled Teaching Yogurt Incubator

SISTEM INOVATIF

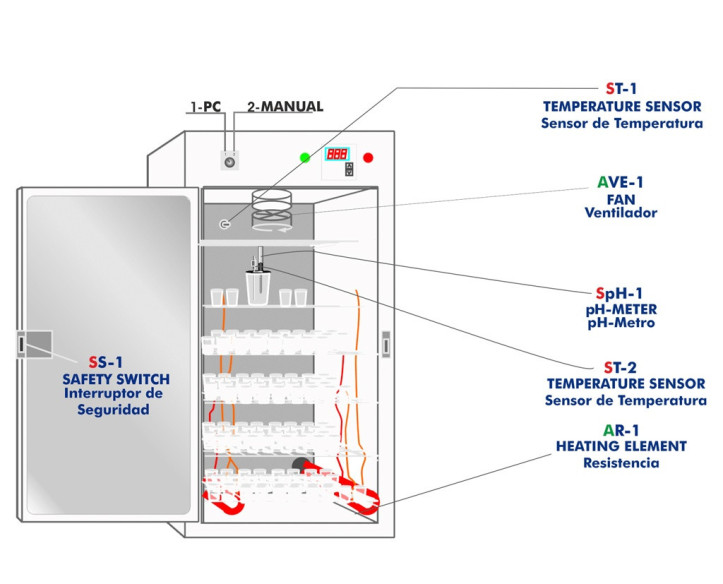

The Computer Controlled Teaching Yogurt Incubator, "IYDC", is called yogurt maker or yogurt heater. This yogurt maker consists of an insulated central body where yogurt fermentation is carried out.

Ekspansi

Laboratorium

BERITA TERKAIT

GAMBARAN UMUM

The Computer Controlled Teaching Yogurt Incubator, "IYDC", is called yogurt maker or yogurt heater. This yogurt maker consists of an insulated central body where yogurt fermentation is carried out.

There is a series of shelves inside to place the containers where yogurts are formed.

There is also a heating element to control the temperature required to make yogurt and a fan to cool down the unit and avoid overheating.

The instrumentation required for a complete monitoring of the process is also included:

- Temperature sensor to measure the temperature inside the unit.

- Temperature sensor to measure the temperature of the yogurt at any moment during the process.

- pH sensor to measure the pH of the yogurt at any moment during the process.

For a safe operation, the unit includes a safety switch to prevent the heating elements from working with the door of the unit open.

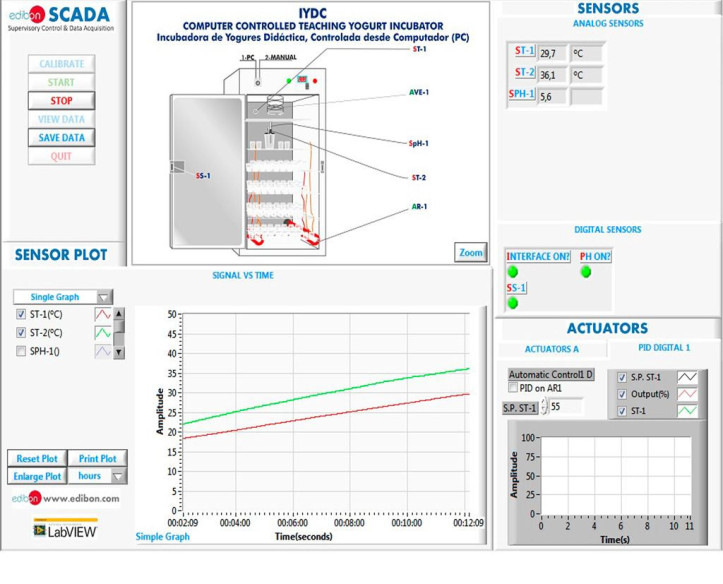

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

LATIHAN DAN PRAKTEK PEDOMAN

LATIHAN PRAKTIS YANG DIANDAL TERMASUK DALAM PANDUAN

- Yogurt making process.

- Measurement of the acidity in the yogurt obtained.

- Measurement of the viscosity in the yogurt obtained.

- Measurement of the two main bacteria used in the yogurt making process.

- Comparison of the results obtained in function of the position of the container in the yogurt maker.

- Viscosity change in function of the yogurt pH.

- Differences in the yogurt when using whole milk or skimmed milk.

- Sensors calibration.

LEBIH BANYAK LATIHAN PRAKTIS YANG AKAN DILAKUKAN DENGAN UNIT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the IYDC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the IYDC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

PERALATAN KOMPLEMENTER

Teaching Cream Separator

Computer Controlled Butter Maker Teaching Unit

Butter Maker Teaching Unit

Unit UHT, Dikendalikan dari Komputer (PC) dengan Layar Sentuh

Computer Controlled Teaching Autonomous Pasteurization Unit

Computer Controlled Laboratory Pasteurizer

Computer Controlled Teaching Curdling Tank

Computer Controlled Teaching Cheese Press

Tangki Keju Gouda untuk Pembuatan Keju (hingga 50 liter)

Computer Controlled Teaching Cottage Cheese Maker

Computer Controlled Cheese Vat

KUALITAS

LAYANAN PURNA JUAL

Preferensi cookie

Preferensi cookie