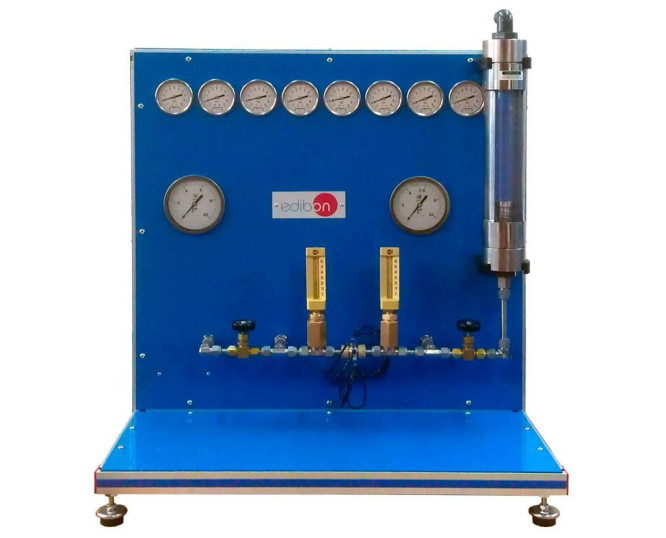

TPT Nozzle Pressure Distribution Unit

INNOVATIVE SYSTEMS

The Nozzle Pressure Distribution Unit "TPT" has been designed to demonstrate the phenomena associated to fluxes through nozzles and to allow the students investigating quickly the pressure distribution in them.

Laboratories

General Description

The Nozzle Pressure Distribution Unit, "TPT", allows to investigate the pressure distribution and the mass flow rate in nozzles (convergentdivergent and convergent nozzles).

The unit includes three types of nozzles:

- Convergent type (conical) nozzle, with six pressure tappings.

- Convergent-divergent nozzle, with five pressure tappings.

- Convergent-divergent nozzle, with eight pressure tappings.

The nozzles are made of brass and have been mechanized accurately. Several pressure tapping are available, being each one connectedto its own manometer.

Compressed air supplied from an external service must be provided to the unit. This air passes through an air filter and pressure regulator to provide constant pressure, clean and water free air to the unit.

In the unit, the air passes through a control valve, which allows an accurate control of the pressure at the inlet of the nozzle. The inlet pressure and inlet temperature are measured and then the air is expanded through the chosen nozzle. When discharging from the nozzle, the pressure is controlled by other valve, and finally the air goes through a flowmeter to the atmosphere. The outlet pressure and outlettemperature are measured before the air passes through the flowmeter.

The unit includes ten manometers: two manometers to indicate the inlet and outlet pressure of the air and the rest to indicate the pressure on the measuring points of the nozzles.

Two thermometers to indicate the air temperature are included.

Exercises and guided practices

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

- Study of the flow in a convergent-divergent nozzle.

- Study of the flow in a convergent nozzle.

- Visual demonstration of the "choking effect".

- Visual demonstration of the pressure distribution.

- Visual demonstration of the counter-pressure on the recompression position.

- Determination of the inlet pressure effect on the mass flow rate with a constant counter-pressure and comparison with the theoretical predictions.

- Determination of the counter-pressure effect on the mass flow rate.

- Observation of the pressure distribution in nozzles.

MORE PRACTICAL EXERCISES TO BE DONE WITH THE UNIT

- Visual demonstration of under expansion and over expansion with re-compression.

- Investigation of the relationship between inlet pressure and mass flow rate.

- Investigation of the relationship between outlet pressure and mass flow rate for a convergent nozzle.

- Investigation of the relationship between outlet pressure and mass flow rate for convergent-divergent nozzles.

- Investigation of the pressure distribution in convergent and convergent-divergent nozzles when working over a variety of overall pressure ratios.

- Study of the effect of air temperature at the nozzles inlet and outlet.

SUPPLEMENTARY EQUIPMENT

Thermal Expansion Training Unit

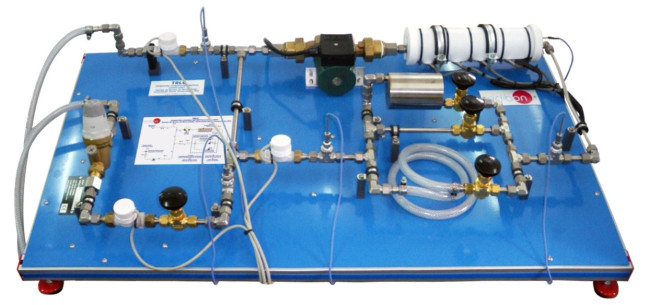

Computer Controlled Expansion Processes of a Perfect Gas Unit

Bomb Calorimeter

Computer Controlled Separating and Throttling Calorimeter

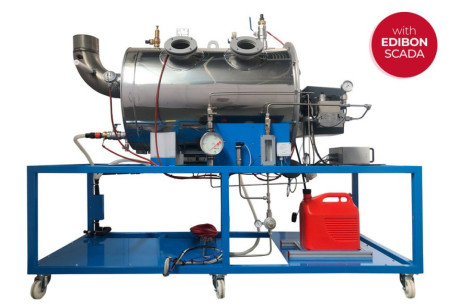

Computer Controlled Marcet Boiler Unit

Computer Controlled Temperature Measurement Unit

Temperature Measurement Unit

Temperature Measurement Training Unit

Computer Controlled Gas Laws Unit (Boyle and Gay-Lussac Laws)

Computer Controlled Recycle Loops Unit

Recycle Loops Unit

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences